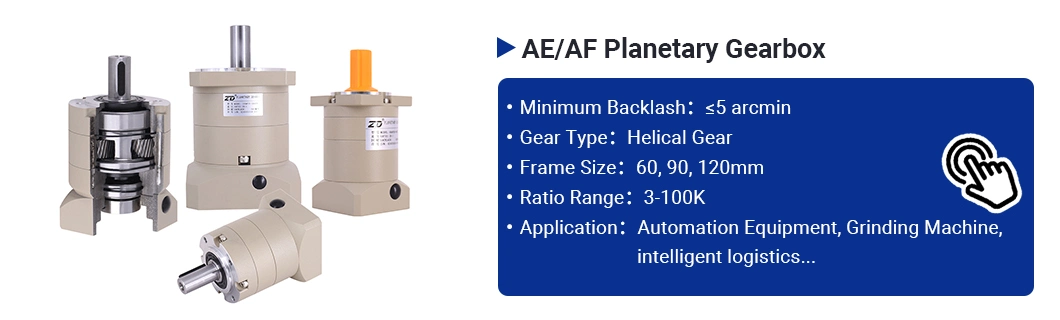

ZD High Precision Low Backlash Spur or Helical Gear Planetary Speed Gear Reducer Gearbox For Servo Motor Steeping Motor

Overview Package size per unit product 25.00cm * 20.00cm * 20.00cm Gross weight per unit product 2.500kg ZD High Precisi

Send your inquiryDESCRIPTION

Basic Info

| Application | Motor, Machinery, Marine, Agricultural Machinery |

| Function | Change Drive Torque, Speed Changing, Speed Reduction, AGV, CNC Machine, Robot |

| Layout | Planetary Gear |

| Hardness | Hardened Tooth Surface |

| Installation | Vertical Type |

| Step | 2-3 Stages |

| Type | Planetary Gear Box |

| Size | 60mm-160mm |

| Reduction Ratio | 3-200K |

| Flange Type | Square/Round Mounting Flange |

| Transport Package | Carton |

| Specification | CE, UL, ISO9001 and RoHS |

| Trademark | ZD |

| Origin | Cixi, Zhejiang, China |

| HS Code | 8483402090 |

| Production Capacity | 30000PCS/Month |

Packaging & Delivery

Package size per unit product 25.00cm * 20.00cm * 20.00cm Gross weight per unit product 2.500kgProduct Description

ZD High Precision Low Backlash Spur or Helical Gear Planetary Speed Gear Reducer Gearbox For Servo Steeping MotorProduct Description

Planetary gearbox is a kind of reducer with wide versatility. The inner gear adopts low carbon alloy steel carburizing quenching and grinding or nitriding process. Planetary gearbox has the characteristics of small structure size, large output torque, high speed ratio, high efficiency, safe and reliable performance, etc. The inner gear of the planetary gearbox can be divided into spur gear and helical gear. Customers can choose the right precision reducer according to the needs of the application.

Model Selection

Click here to find what you are looking for:

Customized Product ServiceCompany ProfileFAQ

Q: What're your main products?

A: We currently produce Brushed Dc Motors, Brushed Dc Gear Motors, Planetary Dc Gear Motors, Brushless Dc Motors, Stepper motors, Ac Motors and High Precision Planetary Gear Box etc. You can check the specifications for above motors on our website and you can email us to recommend needed motors per your specification too.

Q: How to select a suitable motor?

A:If you have motor pictures or drawings to show us, or you have detailed specs like voltage, speed, torque, motor size, working mode of the motor, needed lifetime and noise level etc, please do not hesitate to let us know, then we can recommend suitable motor per your request accordingly.

Q: Do you have a customized service for your standard motors?

A: Yes, we can customize per your request for the voltage, speed, torque and shaft size/shape. If you need additional wires/cables soldered on the terminal or need to add connectors, or capacitors or EMC we can make it too.

Q: Do you have an individual design service for motors?

A: Yes, we would like to design motors individually for our customers, but it may need some mold developing cost and design charge.

Q: What's your lead time?

A: Generally speaking, our regular standard product will need 15-30days, a bit longer for customized products. But we are very flexible on the lead time, it will depend on the specific orders.

Please contact us if you have detailed requests, thank you !